Description

WMS had this machine made to order.

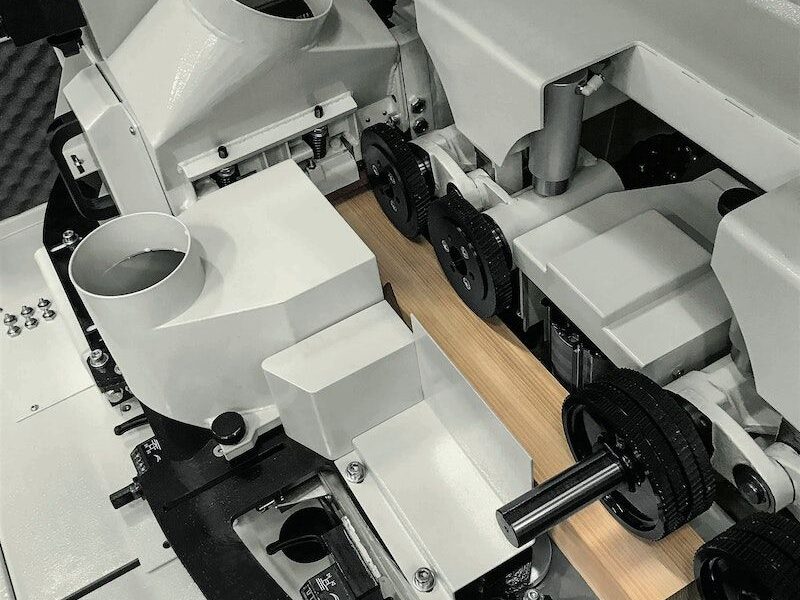

This machine can profile mould on both side heads, the top head and the second bottom head, a composition that lends itself to customers looking for a machine that is ideal for both PAR and Profile Moulding.

The Profiset 60 EP is a throughfeed planer/moulder with easy plus control that automatically moves the top horizontal and left vertical spindle in to there finished height and width positions. The machine comes with optional automatic table lube system and a powerful feed system that can be controlled from the easy plus control unit with speeds of 5-25 m/min. The easy plus 7″ inch display holds a database for both tool and programs to allow for quick set up of different jobs. Pnuematic Pressure for feed rollers and excludable top feed unit fitted in front of bottom horizontal spindle.